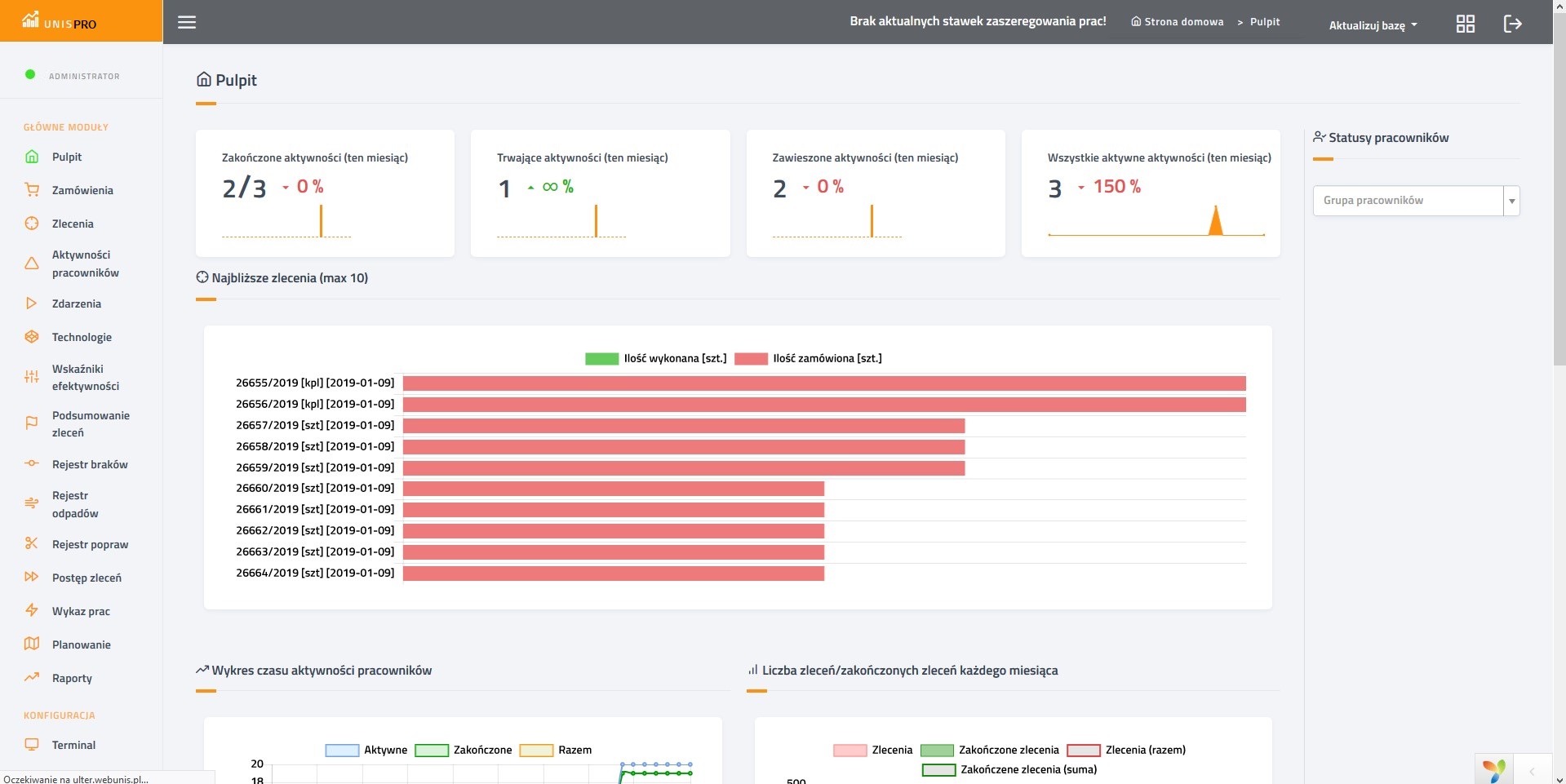

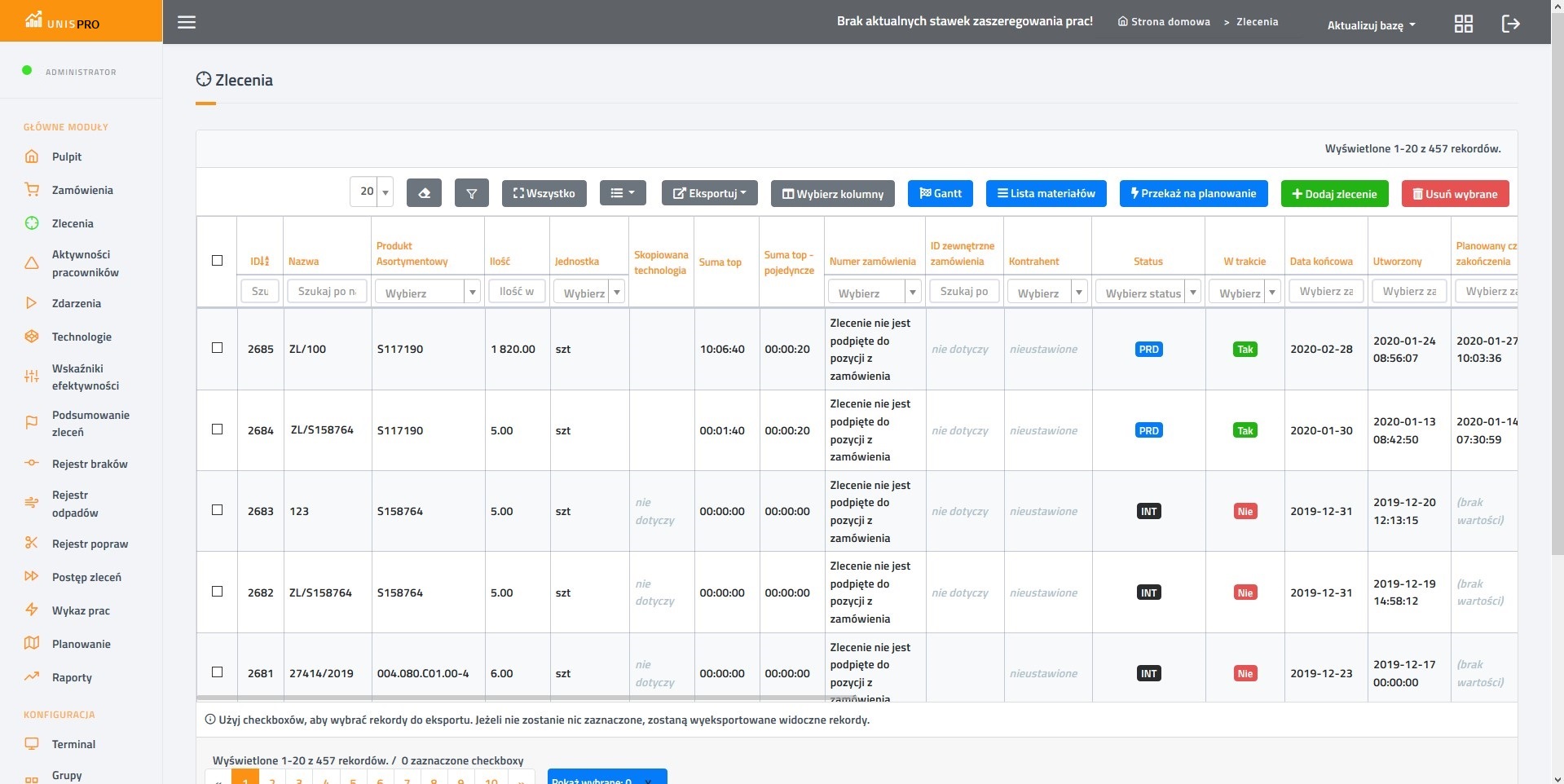

The UNIS PRO system supports the following areas:

- Technical Preparation of Production (TPP)Advanced Planning add Scheduling (APS)

- Control and production registration (CPR)

- Manufacturing Execution System (MES)

- Machine Efficiency (OEE)

- Quality management system (QMS)

- Total Productive Maintenance (TPM)